TM-9-2815-213-34 - Page 47 of 192

•TM 9-2815-213-34

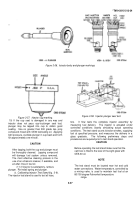

Figure 3-32.

Valve head and collet check.

Figure 3-33. Crosshead guide cheek.

(5) Check valve guide protrusion to limit of

0.695/0.710 inch.

h.

Valve Springs

(fig. 3-35).

NOTE

Weak valve springs may cause flutter

which results in excessive wear on both

valve and seat. Valve flutter interferes

with valve timing and may cause valve to

strike the piston head. Weak springs

may also cause valve warping, cracking

and breaking.

(1) Using a spring tester capable of very

accurate measurements of spring lengths and applied

load, check springs against limits speciflied in repair and

rebuild standards, paragraph 3-183.

NOTE

A 1/32 inch spacer may be used under

valve spring when insert and valve have

been refaced.

(2) Replace springs if load is less than indicated

under "wear limits" at required compressed length.

Figure 3-34.

Valve guide check

Figure 3-35.

Valve spring test.

3-67.

Repair

a.

Resurface Cylinder Head.

Resurface head only

if it has been scratched, etched, or worn unevenly at

point of contact with gasket sealing areas.

(1) Remove a maximum of 0.006 inch of

material.

NOTE

The gasket surface should not deviate

from a true plane

b,

mote than 0.004-

inch.

3-18

Back to Top