TM-9-2815-213-34 - Page 50 of 192

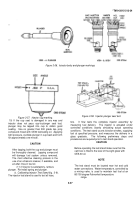

Figure 3-41.

Injector sleeve rolling-upper portion.

Figure 3-42.

Injector sleeve rolling-lower portion

and proper size mandrels to fit reamed valve guides.

Dress grinding stone to 30 degrees from horizontal.

(2)

Grind valve seats, holding motor as

nearly vertical as possible.

(3)

Check valve seat width which should

be 1/16 to ¼/ inch.

(

a

)

If ground seat is wider than 1/8

inch maximum stock can be removed from points "A"

and "B" (fig.

3-29) with specially dressed valve seat

grinder stones.

(

b

) Narrowing should not extend beyond

chamfer on seat insert.

Chamfer provides for peen

metal.

(4) Dress wheel for final finish and finish

grind with light touches of stone against valve seat

face.

(5) Check valve seat concentricity with valve

seat indicator.

(

a

) Use valve guide as a center.

Gage

*

*TM 9-2815-213-34

Figure 3-43.

Injector sleeve seat cutting.

Figure 3-44.

Valve seat insert counterbore.

must be a perfect fit on pilot mandrel.

(

b

) Run out should not exceed 0.002 inch total

indicator reading.

f.

Valve Assemblies

.

Reassemble valve assemblies

in reverse order of disassembly (para.

3-64).

3-69.

Tests

a.

Valve Seating

(

fig.

3-47).

Test valve seating for

leaks with cylinder head gage (2, fig.

B-29) as follows:

CAUTION

Never vacuum test cylinder head with injector

installed.

Installation of injectors could cause

misalignment of valves in valve seat area and result

in leakage during test.

(1) Select a vacuum cup of proper size for

valve to be tested.

3-21

Back to Top