TM-9-2815-213-34 - Page 57 of 192

*TM 9-2815-213-34

(1) Install factory calibrated master injec-

tor gage (36, fig.

B-28), in test stand to adjusting

other injectors for fuel delivery.

CAUTION

The master injector must never be tam-

pered with.

(2) Fill hydraulic fluid reservoir.

(3) Test oil tank on stand must be kept at

least ye full of diesel fuel.

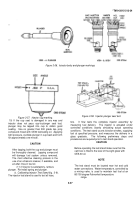

(4) Aline timing mark (fig.

3-60) and close

hydraulic valve and open the air valve (fig.

3-61).

Place load cell tester (1, fig.

B-29) in test stand

and clamp in place by opening hydraulic valve

(fig.

3-61).

CAUTION

Never operate test stand with load cell

in position.

(5) Adjust air pressure by turning knurled

button on air regulator until the load cell indi

cates within marked band on load cell gage (0

3-62).

Lock knurled button in place with lock-

nut.

Note air gage pressure (gage at top

hydraulic reservoir).

(6) Remove load test gage by opening ]

draulic valve and returning air valve knob center

position.

With cylinder rod in down posi- tion, check

to make sure hydraulic fluid shows hydraulic oil lever

sight bulb.

(7) Open air valve.

While cylinder rod is at

the top of its travel, check to make sure there no air

in hydraulic fluid sight glass.

(8) Make sure injector seat contains 0.0

inch restrictor orifice when calibrating test stand.

(9) Place injector adapter (fig.

3-63) o~

master injector and engage locators in inject

mounting holes.

Make sure seat is retracted a timing

marks are alined at timing wheel.

(10) Position test stand link (marked NV NH,

H) over injector plunger link and place adapter and

injector assembly in injector se tip back until link is

below machine push rod.

necessary adjust bracket

so link is alined but r rubbing.

NOTE

Turn injector plunger so that class size

marking on top of spring retainer is midway

between inlet and drain connec- tions.

(11) Open air valve (fig.

3-61) and as

jector goes in clamped position make sure plunk

link is properly alined and engaged in link gui

(12) Check air gage pressure at top of ]

draulic reservoir as originally established with load test cell.

Close hydraulic valve (fig.

3-61) to lock injector in clamped

position.

Connect inlet and drain connectors (fig.

3-64) to

injector.

(13) Start test stand motor and allow to run until fuel

temperature reaches a minimum of 80 degrees.

(14) Adjust fuel pressure by turning pressure

regulator knob until fuel pressure gage

shows 120 psi.

If this pressure can not be achieved, the

trouble probably is due to a sticking air regulator, or to a worn

gear pump.

Pres.

sure of 120 psi must be maintained at all

times during calibration and testing.

(15) All counter wheels (fig.

3-60) must be set at

zero (0) as a starting point.

(a) Shift silver-colored counter wheels to right, rotate as

necessary then release them to indicate 1020 strokes.

Rotate empty vial into position by turning vial knob.

(b) Clear counter by rotating with thumb screw until all white

counter wheels show zero.

(16)

Engage

counter

and

divert fuel to vial for measurement by pressing and releasing

red flow start switch.

(17) Stir fuel with a rod to settle out foam.

Check

amount collected in vial at end of 1020 counter strokes.

(18) Look directly into vial at fuel level to avoid

parallax.

If this reading shows 129 cc which is 3 cc below

correct injector master de livery specifications (132 cc @ 120

psi.), or an- other value, repeat test.

(19) Dump fuel from vial and repeat test at least

twice to insure consistent results.

(20) If 3 cc low, it will be necessary to set counter up

to approximately 1043 strokes or

about 71/2 strokes for each cc.

Roll counter back,

all white counter wheels must show zero (0).

(21) Repeat

tests and adjust counter as necessary to obtain 132 cc

delivery at 120 psi.

with fuel temperature at 80 degrees to

100 degrees Fahrenheit while master injector is in test stand.

Check readings for three cycles to insure repeatability, at this

point test stand is correctly

calibrated.

(22) Remove master injector from test

stand.

c.

Injector Spray Pattern Check.

(1) Locate injector spray angle tester (6, fig.

B-29)

on or near injector test stand (fig.

3- 59) or other source of

50 p.s.i.

constant fuel pressure, so that injector inlet

connection of test stand will reach injector to be checked.

Use injector test oil or diesel fuel to perform test.

3-28

Back to Top