TM-9-2815-213-34 - Page 63 of 192

*TM 9-2815-213-34

at each of remaining positions shown above (16 and

6.0 BTC).

If push rod travel is greater or le than

limits shown, timing is slow or fast respectively.

A

new camshaft key must be installed bring push rod

travel within limits.

Refer to paragraph 212.k.

for

removal of shaft, and pal graph 3-30 for disassembly.

NOTE

Before installing new key, make sure

guide spring on tappet body is not hold-

ing tappet off camshaft lobe.

i.

Recheck limits as outlined in Chart 3-1.

j.

Remove timing fixture and injector push rod.

Section XV.

Repair of Rocker Arm Assembly and Push Rods

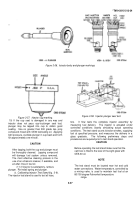

3-80.

Disassembly

(fig.

B-6)

a.

Remove locating socket head stew

(44)

from mounting bracket (8).

The rocker shaft locating

socket head screws are located on rear left bank and

front of right bank assemblies.

b.

Slide rocker arm shaft brackets and rock

arms (47, 50, and 52) from the shaft (46).

c.

Remove rocker arm shaft plugs (45) from

each end of each shaft.

d.

Remove adjusting screws (55) and

locknut

(54) from rocker arms.

3.81.

Cleaning

Clean all parts in accordance with paragraph 2

3-82.

Inspection

a.

Rocker Arm Assembly

(1) Perform general inspection of rocker arm

assembly in accordance with paragraph 2-8

(2) Gage rocker lever bushings with tele

scope gage and micrometer.

(a) Set telescopic gage 0.0002 inch above

worn limit of 1.1905 inches for use as a plug gage.

NOTE

The inside diameter of a new rocker arm

bushing is 1.1875/1.1895 inches and may

wear to 1.1905 inches maximum.

(b) Replace bushings worn beyond limits

(para.

d, below).

(3) Check intake and exhaust rocker arm

crosshead contact surface.

If worn or damaged,

replace with new rocker arm.

(4) The ball end of rocker arm adjusting

screws must be true spheres.

Test with 1/4 inch

radius gage and replace worn adjusting screw

(5) Worn injector rocker arm sockets must

be replaced.

Wear is easily detected with fillet

gage or by observation of small protrusion at the

bottom of socket.

(6) Check that all lubricating oil passages

are open.

(7) Inspect thread condition on all screws and rocker

arms.

Check closely for thread dam- age at assembled

position of locknut.

Ensure

that screws operate freely through rocker arms.

(8) Check rocker arm shaft for scoring, galling, out-

of-round and wear.

If worn smaller than 1.1845 inches,

install new shaft.

NOTE

New rocker arm shaft measures 1.1856/

1.1865 inches with a wear limit to 1.1845

inches,

(9) Examine rocker arm shaft brackets for cracks,

breaks and stripped threads.

Replace as necessary.

(10) Visually inspect arm side surfaces which mate

with adjacent arms.

If galled, grind surfaces to original

smoothness.

b.

Push Rods.

(1) Check ball end of all push rods for worn radii.

A

new allowance of 0.3150 inch.

Check in- jector and valve

push rod ball ends with 5/16 inch radius gage.

(2) Test sockets of push rods with ball end of a new

rocker lever adjusting screw or with 1/4 inch fillet gage.

(3) Replace defective push rods.

Extreme wear on

either end of push rod will result in loss of lubricating oil

pressure and may interfere with proper injector and valve

adjustment.

3-83.

Repair

Repair of the rocker arm assembly and push rods is limited

to replacement of defective parts.

Re- place rocker arm

bushing as follows:

a.

Press out worn bushing with mandrel and

block set (4, fig.

B-28).

3-34

Back to Top