TM-9-2815-213-34 - Page 65 of 192

*TM 9-2815-213-34

Section XVIII.

Repair of Air Compressor and Drive Assembly

3-96.

Disassembly

a.

Remove drive gear and woodruff from shaft

b.

If inspection indicates need, remove sleeve

bushing from air compressor rear support.

3-97.

Cleaning

Clean air compressor and drive assembly in accor-

dance with paragraph 2-5.

3-98.

Inspection

a.

Inspect oil flow passage in air compressor rear

support to insure unrestricted passage.

b.

Inspect air compressor rear support sleeve

bushing for wear, restricted oil groove, and alinement

of oil ports in support.

Replace bushing if excessive

wear is evident.

c.

Inspect drive gear against specified limits in

repair and rebuild standards paragraph 3-136.

Replace gear if outside limits specified.

d Inspect air compressor in accordance with

paragraph 2-6.

3-99.

Repair

Repair of air compressor and drive assembly is

limited to replacement of spared parts or units

3-100.

Assembly

a.

Install drive gear on drive shaft.

b.

Press sleeve bushing into air compress rear

support.

CAUTION

Be sure that oil ports in sleeve bushing are alined with

corresponding oil ports in rear

support.

3-101.

Installation

a.

Slide air compressor and drive assembly with new gasket,

into engagement of drive gear with camshaft gear.

CAUTION

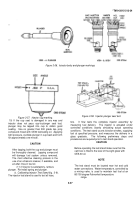

Be sure that "O" index mark on drive gear tooth (fig.

3-72) is alined between the two punched-marked

teeth on camshaft gear.

b.

Secure assembly snug tight only with three capscrews as

shown in figure 8-78.

c.

Attach a dial indicator to flywheel housing as shown in

figure 3-70.

d.

Advance drive gear as far as possible and set dial

indicator to zero.

e.

Retard drive gear and note indicator reading.

NOTE

Indicator reading should be within 0.006-0.009

inch.

If reading is outside these limits, gear train

must be replaced.

f.

Remove capscrews and lockwashers (step b.).

g.

Install rear support on drive shaft and position to housing

securing support with five capscrews and lockwashers.

Section XIX.

Repair of Fuel Pump and fuel Lines

3-102.

Disassembly

NOTE

Perform the requirements of paragraph

3-104 a through d before disassembling the

pump.

If the pump operation is in ac-

cordance with the specified requirement of

these paragraphs, proceed to paragraph 3-

107

(fuel

pump

test

and

calibration

Disassembly of the pump will not be

necessary.

a.

Disassembly Into Sub-assemblies

.

Mount

fuel

pump (fig.

3-73) to fuel pump mounting plate and

ball joint vise (1 and 2, fig.

28) as shown in figure

3-74.

(1)

Fuel shut-off solenoid valve assembly

B-17).

(a) Remove two capscrews, lockwashers, and

flat washers (3, 4, and 5) securing valve to pump.

(b) Remove valve (1).

Discard O-Ring (17).

(c) Remove four screws and lockwashers (14

and 15) securing coil assembly (13) to pump housing

(6).

(d) Remove shield (12), O-Rings (8 and 11), spr-

ing (10), and valve (9).

(e) Remove knob (18) on manual override shaft

(7) and remove shaft.

(f) Remove outlet connection (2) and pipe plug

(16).

(2)

Fuel pump damper assembly

(fig.

B-16).

(a) Remove two capscrews, lockwashers, and

flat washer (23, 24, and 25) securing damper assembly

to pump gear assembly.

3-36

Back to Top