TM-5-2350-377-14-P - Page 51 of 335

TM 5-2350-377-14&P

GENERAL HYDRAULIC SYSTEM REPAIR METHODS - continued

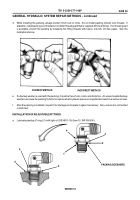

b. 37° Flare.

The 37° flare termination has a male straight thread that mates with a female straight thread.

The sealing

surface for this termination is the angled nose at the end of the male fitting.

This nose mates with a similar surface

in the female 37° flare fitting.

These sealing surfaces must be free of nicks and scratches in order to seal properly.

If nicked or scratched, item must be replaced.

For torque requirements, see guide on page 0008 00-14.

CAUTION

Packing must be seated fully into groove and not on threads.

Failure to comply may damage

packing, resulting in damage to equipment.

c. O-ring (preformed packing) Boss.

This termination also has a straight thread.

The seal for this termination is a

preformed packing that fits at the top of the threads on the male fitting.

This packing is squeezed into the extra space

at the top of the threads of the female fitting and seals the connection.

The installed packing must be free of nicks

and cuts to seal properly.

If packing is nicked or cut, it must be replaced.

d. Flareless.

This fitting also uses a straight thread.

The female fitting contains a ferrule that mates with a cavity in

the male fitting.

Use recommended torque values to tighten nut (page 0008 00-14).

If this fitting is over torqued,

the ferrule will be deformed and the fitting will leak.

0008 00-10

0008 00

SEALING

SURFACE

SLEEVE

NUT

O-RING (PACKING)

O-RING (PACKING) CAVITY

O-RING (PACKING) BOSS

STRAIGHT THREAD

Back to Top