TM-5-2350-377-14-P - Page 54 of 335

TM 5-2350-377-14&P

GENERAL HYDRAULIC SYSTEM REPAIR METHODS - continued

CAUTION

Packing must be located fully in groove and not on threads, or packing will be damaged,

resulting in damage to equipment.

b. Gently push backup washer (2) and packing (1) all the way into groove (3).

c. Turn locknut (4) down until it just contacts the backup washer (2).

d. Install fitting, by hand, into boss (5) until the backup washer (2) contacts the face of the boss (5).

e. Position the fitting to the desired position by backing it out (counterclockwise) to 1 full turn.

Hold the fitting in the

desired position and tighten locknut (4) with a wrench.

f.

Assemble tube to fitting after fitting is properly positioned and tightened.

GENERAL QUICK-DISCONNECT REPAIR METHODS

The hydraulic, pneumatic, and fuel systems on the M9, Armored Combat Earthmover with HBF-TT use quick-

disconnects on many hoses.

All are similar.

A faulty or damaged quick-disconnect can obstruct flow through the affected

hose.

To disassembly and assemble a damaged or leaking quick-disconnect, use the following procedures.

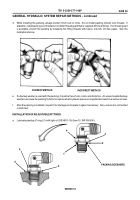

DISASSEMBLY

NOTE

Use two wrenches to disassemble and assemble quick-disconnects.

a. Remove adapters (1) from hoses (2).

b. Remove adapters (1) and packings (3) from quick-disconnect coupling halves (4).

Discard packings (3).

c. Separate quick-disconnect coupling halves (4) by aligning arrow on collar and pulling collar.

ASSEMBLY

a. Coat packings (3) with lubricating oil.

(OE/HDO-10) (Item 15, WP 0055 00).

b. Install packings (3) and adapters (1) in quick-disconnect coupling halves (4).

0008 00-13

0008 00

2

2

1

3

4

3

1

Back to Top