TM-5-2350-377-14-P - Page 49 of 335

TM 5-2350-377-14&P

WIRING HARNESS AND CABLE REPAIR - continued

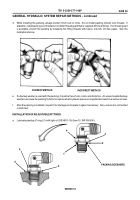

FEMALE CABLE CONNECTOR (WITH SLEEVE) REPLACEMENT

a. Strip cable insulation aproximately 1/8 inch (3 mm).

b. Slide shell and sleeve over cable.

c. Insert cable in cylindrical end of terminal and crimp.

d. Slide shell and sleeve over terminal.

GENERAL HYDRAULIC SYSTEM REPAIR METHODS

This section contains repair methods for the hydraulic system.

If special repair methods or procedures are required for

the hydraulic system components or parts, specific repair instructions are included in the individual maintenance tasks.

WARNING

High pressure is present in the M9 hydraulic system.

Do not disconnect any hydraulic

system component unless hydraulic system pressure has been relieved.

After hydraulic

system pressure has been relieved, wait at least 4 minutes before disconnecting any

hose or fitting.

Failure to comply may result in severe injury to personnel.

Spilled hydraulic oil is very slippery.

Use caution when entering or working in bowl

area.

Wipe up any spilled oil immediately.

Failure to comply may result in severe

injury to personnel.

CAUTION

ALWAYS clean around fittings before disconnecting or connecting hoses or fittings.

Ensure

area is clean before installing hydraulic components.

Failure to comply may result in damage

to equipment.

Cover, cap, or plug all openings, ports, and tube or hose ends when disconnected.

Failure to

comply may result in damage to equipment.

Ensure fittings are connected to fittings of the same design or damage to equipment may result.

Connecting unlike fittings may not damage threads, but is not a guarantee that the connection

will not leak.

See illustrations of fitting types on pages 0008 00-9 through 0008 00-12.

Fittings must be installed and tightened.

If a fitting cannot be tightened, it may be cross-

threaded or have damaged threads.

Failure to comply may result in damage to equipment.

Use

wrench only for final tightening.

0008 00-8

0008 00

SLEEVE

CABLE

SHELL

TERMINAL

Back to Top