TM-5-2350-377-14-P - Page 50 of 335

TM 5-2350-377-14&P

GENERAL HYDRAULIC SYSTEM REPAIR METHODS - continued

CAUTION - continued

Do not use TEFLON tape as a sealer on any fittings.

It can separate from the fittings and cause

control valves, relief valves, and actuators to become contaminated and fail.

Failure to comply

may result in damage to equipment.

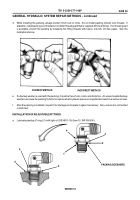

It is possible to connect a male national pipe thread (NPT) to a female straight thread, but the

fitting will leak.

Learn to recognize the very slight taper which an NPT has (see illustration

below).

Do not attempt to connect NPT and female straight threads.

Failure to comply may

result in damage to equipment.

Do not attempt to use the parts of the 37° flare fitting and the flareless fitting with each other.

The connection will leak.

Use caution when connecting NPTs.

If overtightened, the female pipe thread will split.

If a

connection leaks, disconnect and apply thread sealant.

Reconnect the threads and snug up

with wrench.

Failure to comply may result in damage to equipment.

Do not apply sealant to the first threads of NPT fittings.

If sealant enters the hydraulic system,

it may cause components to fail.

Use caution when installing preformed packings.

Sharp threads can nick the packing, causing

connection to leak.

Failure to comply may result in damage to equipment.

If fitting leaks, check

packing for nicks or cuts and replace if necessary.

Do not overtighten a flareless connection.

Observe torque values on page 0008 00-14.

Overtightening can cause leakage, requiring replacement of entire tube assembly.

When connecting a hose to a fitting, ALWAYS USE TWO WRENCHES.

Use one wrench to

turn the swivel nut onto the fittings, and use another wrench to keep the fitting from rotating.

The following information is provided to familiarize personnel with the various types of hydraulic fittings.

Refer to this

section and the warnings and cautions on the previous page when working on hydraulic systems.

a. National Pipe Thread (NPT).

This thread is commonly found in hydraulic systems.

It differs from other fittings in

that it is tapered.

In order to obtain a proper seal with this thread, you must use a sealant.

The sealant should be

applied to the male fitting.

Torque value guide in this work package, is NOT to be used.

CAUTION

Do not apply sealant to the first threads of fittings.

If sealant enters into the hydraulic system,

it may cause components to fail.

0008 00-9

0008 00

DO NOT APPLY

SEALANT TO

FIRST THREAD

NOTE TAPER

NATIONAL PIPE THREAD (NPT)

Back to Top