TM-5-2350-378-24-P - Page 568 of 790

TM 5--2350--378--24&P

0031 00--1

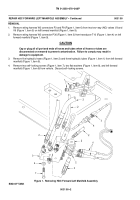

REPAIR HDC FORWARD LEFT MANIFOLD ASSEMBLY

0031 00

THIS WORK PACKAGE COVERS:

Removal, Disassembly, Assembly, Installation

INITIAL SETUP:

Tools and Special Tools

General Mechanic’s Tool Kit (WP 0071 00, item 7)

Materials/Parts

Dust protective caps (2) (WP 0070 00, item 1)

Dust protective caps (2) (WP 0070 00, item 2)

Dust protective caps (4) (WP 0070 00, item 3)

Dust protective plugs (2) (WP 0070 00, item 5)

Dust protective plugs (2) (WP 0070 00, item 6)

Dust protective plugs (4) (WP 0070 00, item 7)

O--ring (3) (WP 0072 00, item 7)

O--rings (4) (WP 0072 00, item 8)

O--rings (2) (WP 0072 00, item 9)

O--rings (2) (WP 0072 00, item 5)

O--rings (2) (WP 0072 00, item 6)

Teflon backups (4) (WP 0072 00, item 1)

Materials/Parts -- Continued

Self--locking screws (2) (WP 0072 00, item 17)

Wiping rags (WP 0070 00, item 9)

Personnel Required

Two 62B10

Equipment Conditions

Hydraulic pressure relieved (WP 0004 00)

Vehicle MASTER power OFF (TM 5--2350--262--10)

Vehicle hull raised and on jack stands

(TM 5--2350--262--20--1)

Hull access plates removed (TM 5--2350--262--20--1)

WARNING

S

High oil pressure is present in the M9 hydraulic system. Do not disconnect any

hydraulic system component unless hydraulic system pressure has been relieved.

After hydraulic system has been relieved, wait at least 4 minutes before

disconnecting any hose or fitting. Ensure each of the hydraulic control levers is

moved several times through all positions and the hydraulic tank dipstick is slowly

loosened to relieve pressure. Failure to comply may result in severe injury or death

to personnel.

S

Do not work under vehicle unless hull is on jack stands and apron lockpins are

installed. Failure to comply may result in severe injury or death to personnel.

NOTE

All removal steps are accomplished through ac-

cess under vehicle.

Tag all hydraulic lines and wiring harness leads

being disconnected to assist in installation.

Back to Top