TM-9-1200-215-34-P - Page 119 of 266

TM 9–1200–215–34&P

4–5

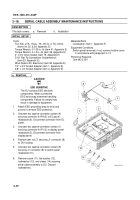

4–11.

MANUAL TROUBLESHOOTING PROCEDURE

DESCRIPTION

This task covers:

Manual Troubleshooting

INITIAL SETUP

Tools:

Tool Kit, JTK–17LAL (item 34, Appendix E)

Tool Kit, General Mechanic’s (item 42, Appendix E)

Electronic Shop, Transportable, AN/TSM–191(V)3

(item 11, Appendix E)

Work Station Kit ESD (item 38, Appendix E)

Test Program Set, LRU (item 37, Appendix E)

Equipment Condition:

Unenergized PDIU on workbench

Personnel Required:

One MOS 35Y

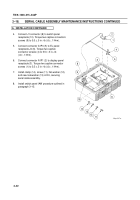

CAUTION

ESD SENSITIVE

This procedure involves electrostatic discharge (ESD)

sensitive parts.

Operator must be properly grounded to

static pad set before handling equipment.

NOTE

PDIU Assembly TPS–LRU must be loaded into the

AN/TSM–191(V)3 before attempting this procedure.

This task covers PDIU test before and after

maintenance.

MANUAL TROUBLESHOOTING

1.

Attach ESD grounding strap to wrist and ground to ensure ESD protection.

2.

Select and load the PDIU Test Program.

3.

At system video display, enter steps to begin test.

4.

Follow instructions shown on video display and connect PDIU assembly to AN/TSM–191(V)3.

5.

Observe test results and instructions on terminal display.

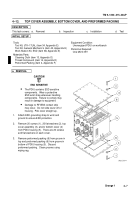

NOTE

If PDIU passes all tests, perform steps 6 and 7.

If

PDIU fails tests, perform steps 8 and 9.

6.

Remove PDIU assembly from AN/TSM–191(V)3.

7.

Forward PDIU assembly to spares stores.

8.

Forward PDIU assembly to appropriate repair activity with test results.

9.

Repair faulty PDIU component in accordance with procedures in Section V and repair parts authorized in

Appendix C.

For repair beyond field level, forward to Depot.

Back to Top