TM-9-1200-215-34-P - Page 111 of 266

TM 9–1200–215–34&P

3–20

3–18.

SERIAL CABLE ASSEMBLY MAINTENANCE INSTRUCTIONS

DESCRIPTION

This task covers:

a.

Removal

b.

Installation

INITIAL SETUP

Tools:

Tool Kits, JTK–17LAL, TK–101/G, or TK–105/G

(items 34, 35, & 36, Appendix E)

Torque Wrench, 0–150 in.–lb (item 41, Appendix E)

Torque Wrench, 0–15 in.–lb (item 39, Appendix E)

2” x 3/4” Drive Socket (item 19, Appendix E)

3/16” Flat Tip Screwdriver Socketwrench

(item 23, Appendix E)

Work Station Kit, Electronic (item 38, Appendix E)

1/2” x 3/4” Socket Adapter (item 1, Appendix E)

3/8” x 1/2” Socket Adapter (item 2, Appendix E)

Materials/Parts:

Lockwasher (item 1, Appendix F)

Equipment Conditions:

Switch panel removed; if not, remove bottom cover

in accordance with paragraph 3–13

Personnel Required:

One MOS 35Y

a.

REMOVAL

CAUTION

ESD SENSITIVE

The DU contains ESD sensitive

components. Wear a protective

ESD wrist strap whenever handling

components. Failure to comply may

result in damage to equipment.

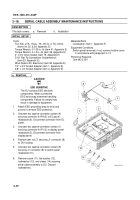

1.

Attach ESD grounding strap to wrist and

ground, to ensure ESD protection.

2.

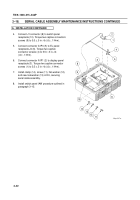

Unscrew two captive connector screws (4)

securing connector A1P4 (5) to EL panel

receptacle (6). Disconnect connector from EL

panel.

3.

Unscrew two captive connector screws (1)

securing connector A1P1 (2) to display panel

receptacle (3). Disconnect connector from

display panel.

4.

Remove jam nut (7) securing J1 connector (8)

to DU housing.

5.

Unscrew two captive connector screws (9)

securing J1 connector (8) to switch panel

receptacle (10).

6.

Remove screw (11), flat washer (12),

lockwasher (13), and clamp (14) securing

serial cable assembly to DU. Discard

lockwashers.

8

9

7

10

14

12

13

11

6

3

4

5

1

2

Back to Top