TM-9-2815-205-24 - Page 602 of 856

INSPECTION-ACCEPTANCE AND REJECTION CRITERIA

1.

Inspect all parts for signs of damage, corrosion, or deterioration. Check for nicked, crossed, or

stripped threads.

2.

Check turbine wheel for nicks, rubbing, and wear.

3.

Inspect shaft for signs of scoring, scratches, or bearing seizure.

4.

Check compressor wheel for signs of rubbing or blade damage. Check to see wheel bore is not galled.

5.

Inspect seal parts for signs of rubbing or scoring of running faces.

6.

Inspect backplate for wear or damaged bore.

7.

Inspect center housing for contact with rotating parts.

END OF TASK

ASSEMBLY

1.

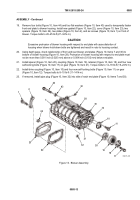

Lubricate new bearing (Figure 5, Item 26) and new bearing (Figure 5, Item 30) with engine oil.

2.

Install new inner retaining ring (Figure 5, Item 32), new flat washer (Figure 5, Item 31), new bearing

(Figure 5, Item 30), and new outer retaining ring (Figure 5, Item 29) in compressor end of center

housing (Figure 5, Item 2).

3.

Install new retaining ring (Figure 5, Item 28), new flat washer (Figure 5, Item 27), and bearing

(Figure 5, Item 26) in compressor end of center housing (Figure 5, Item 2).

4.

On models 5063-5392, 5063-5393, and 5063-539L, insert thrust collar (Figure 5, Item 24) into new thrust

washer (Figure 5, Item 25) and install thrust collar, thrust washer, and three new socket head screws

(Figure 5, Item 33) in center housing (Figure 5, Item 2). Torque screws to 30–35 lb-in. (3.4–3.9 N·m).

5.

Install new seal ring (Figure 5, Item 21) in groove at compressor end of center housing (Figure 5, Item 2).

21

24

31

30

29

28

27

26

25

32

2

33

MAINT_308

Figure 5.

Turbo Center Housing Assembly.

TM 9-2815-205-24

0086

0086-6

Back to Top