TM-9-1200-215-34-P - Page 93 of 266

TM 9–1200–215–34&P

3–2

(1)

Inspect the equipment for damage incurred during shipment. If the equipment has been damaged, report

the damage on SF 364, Report of Discrepancy.

(2)

Check the equipment against the packing slip to see if the shipment is complete. Report all

discrepancies in accordance with the instructions of DA PAM 738–750.

c.

Processing unpacked equipment. Enter unpacked and checked equipment into normal work schedule based

on standard shop practice

Section

III – PRE–SHOP ANAL

YSIS

Page

Page

Introduction

3–2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–shop Analysis

3–2

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6.

INTRODUCTION

Pre–shop analysis is a method for screening incoming equipment to determine its physical condition for

maintenance tasks required to return the equipment to service. Pre–shop analysis begins with a technical

inspection of the equipment and ends with a report of corrective actions taken. Other than for structural

malfunctions, such as broken handles, all incoming equipment is subject to manual troubleshooting as outlined in

Section IV of this chapter.

3–7.

PRE–SHOP ANALYSIS

Using Table 3–1 and paragraph 1–11 as a guide, check for parts that are broken, cracked, bent, dented, or

missing. Evaluate condition of assembly. Verify that all cable receptacles are securely fastened. Acceptable

cracks and dents should be cleaned and missing Chemical Agent Resistant Coating (CARC) should be reapplied.

WARNING

Uncured CARC paint contains hazardous materials. Follow manufacturer’s instruction in

preparation and application of the CARC. Failure to comply may result in injury to personnel.

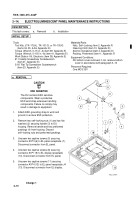

Table 3–1. Pre–shop Analysis Guide

Item

Description

Check

Action

1

Forms and Tags

Existence.

Determine reason for sending LRU to

maintenance.

2

Receptacle: J1

Cleanliness, corrosion, bent pins,

cracks, and broken or worn con-

nector lugs.

Tighten, clean or forward to depot as

appropriate.

3

Switch Panel

Cleanliness, broken toggle covers,

cracks, cracked/cut environmental

key covers, and burnt out LEDs.

Clean, evaluate or replace as required.

4

Electrolumines–

cent Panel

Cleanliness, cracks, fuzzy display.

Clean, evaluate or replace as required.

5

Handle

Existence, function, and cracks.

Replace as required.

6

Enclosure

Cleanliness, corrosion, dents,

cracks, broken vanes and mount-

ing feet, and markings and paint.

Condition of

inlet valve.

Clean, evaluate, spot paint, or forward to

depot as appropriate. Replace inlet valve

per paragraph 1–24.

Change 1

Back to Top