TM-9-1200-215-34-P - Page 96 of 266

TM 9–1200–215–34&P

3–5

3–10.

MANUAL TROUBLESHOOTING PROCEDURES

DESCRIPTION

This task covers:

Manual Troubleshooting

INITIAL SETUP

Tools:

Tool Kits, JTK–17LAL, TK–101/G, or TK–105/G

(items 34, 35, & 36, Appendix E)

Pin Adapter, Test #16, #20, and #22

(items 4, 5, & 6, Appendix E)

Socket Adapter, Test #16, #20, and #22

(items 7, 8, & 9, Appendix E)

Electrical Lead (item 14, Appendix E)

Equipment Conditions:

Appropriate cable assembly removed; if not, remove

appropriate cable assembly in accordance with

procedure in paragraphs 3–17 or 3–18 as

required.

Personnel Required:

One MOS 35Y

NOTE

•

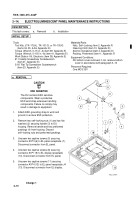

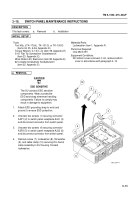

The following troubleshooting procedures consist of wiring diagrams locating box edge

connector pins to internal harness connector terminations. Continuity checks using these

diagrams are intended to be used when replacement of internal components fails to correct

an Electronic Shop, Transportable, AN/TSM–191(V)3, indicated fault. All other internal

troubleshooting will be performed by automated testing. Refer to TPS 12958912 for specific

DU troubleshooting procedures.

•

The continuity check is performed to test for the existence of a connection between two

contacts on the cable. The two probes from an ohmmeter are touched to the appropriate pair

of contacts and the ohmmeter is monitored. Low resistance readings (approaching 0 ohms)

show a good connection; high resistance readings (approaching infinity) show degraded or

broken connection. Figure 3–2 shows what contacts the probes should be placed on to check

for continuity on the DU–Keyboard cable assembly. Figure 3–3 shows what contacts the

probes should be placed on to check for continuity on the DU–Serial cable assembly.

MANUAL TROUBLESHOOTING

1.

Check for continuity using figures 3–2 and 3–3.

11

10

9

8

7

3

2

1

21

20

1

6

5

2

4

9

3

7

8

13

A1P3

A2P1

Figure 3–2. DU–Keyboard Cable Assembly

Back to Top