TM-9-2320-273-34 - Page 478 of 801

TM 9-2320-273-34

(4)

Starting with 0.000 end play, tighten each adjusting ring one notch. This will properly

preload the differential bearings.

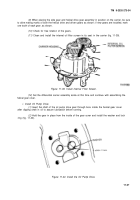

e. Check Hypoid Gear Back/ash.

If the drive gear is not going to be replaced, the established backlash

recorded before disassembly should be used. For new gears the new backlash should be initially set at

0.010 in. (0.254 mm). Adjust backlash (fig. 11-31) by moving the gear only. This is done by backing off

one adiustinq ring and advancing the opposite ring the same amount.

Figure 11-31. Check Gear Backlash.

-— .

._

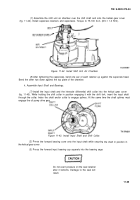

f. Check Tooth Contact (fig. 11-32).

Figure 11-32. Satisfactory

TOOTH CONTACT

(GEARS UNLOADED)

(1)

Apply a red lead compound (item 26, App B) lightly to the gear teeth. When the pinion is

rotated, the red lead is squeezed away by the contact of the teeth, leaving bare areas the exact size, shape,

and location of the contacts.

(2)

Sharper hand roll impressions may be obtained by applying a small amount of resistance to

the gear with a flat steel bar and using a wrench to rotate the pinion.

When making adjustments, check the

drive side of the gear teeth. Coast side should be automatically correct when drive side is correct. As a

rule, coating about twelve teeth is sufficient for checking purposes.

11-32

Hypoid Contact.

Back to Top