TM-9-2320-273-34 - Page 473 of 801

TM 9-2320-273-34

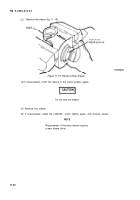

(17) Start turning in pinion cage capscrews approximate y three turns each and alternating to

other capscrews. This will avoid cocking the cage in the carrier while the capscrews push the cage into

position. When the cage is seated in the carrier loosen the capscrews and then retighten to torque of

80-105 Ib-ft (108-142 N•m).

b. Assemble the Differential Case and Gear.

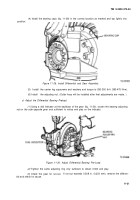

The ring gear should not be pressed or

driven on the case, as this would cause

excessive metal particles to lodge between

the gear and the case, thus resulting in

gear run-out. Proper installation should,

therefore, incorporate preheating the gear

to assure correct interference fit and to

eliminate metal pick up.

(1) Heat the ring gear in oil to approximately 1600°F-1800°F (71.1°C-82.2°C) for about ten

minutes before assembly.

(2) If ring gear has been separated frorm case, fasten with twelve bolts, washers, and nuts.

Torque to 180-230 ib-ft (244-312 N°m).

(3) Assemble and install no-spin assembly as follows.

(a)

Lightly lubricate all parts with recommended gear case lubricant (item 30, App B).

(b) Lay ring gear and large half of case on bench with the bearing end of case hub down

and the inner case facing upward. Be

sure no thrust washers are inside the case.

(c) Place the ground hub of a side gear into the bore of the case, being sure the side gear

will rotate freely in the case. Some two-speed axles use different length side gears and the correct side gear

must be used.

11-27

CAUTION

Back to Top