TM-9-2320-273-34 - Page 471 of 801

TM 9-2320-273-34

a. Assemble Pinion and Cage Assembly.

NOTE

Before assembling, coat all parts of

bearings with recommended axle

lubricant (item 30, App B).

(1)

Press rear bearing firmly against the pinion shoulder with a suitable sleeve against the bearing

inner race.

(2)

press the spigot bearing into position on the pinion end.

(3)

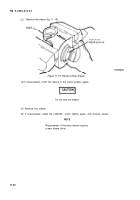

T

O

retain the spigot bearing on the pinion end, it is necessary to stake the pinion

points (fig. 11-23). Use the proper staking tool to fit over the end of the pinion and spigot beari

correctly achieve this.

Figure 11-23, Stake Pinion.

Do not strike the spigot bearing or attempt

to stake bearing onto pinion using a punch

and hammer – damage will result. Staking

points are not to be spotted at the root

angle grooves of the pinion (if present) or

in the original staking points if using the

original bearing.

at three

ng to

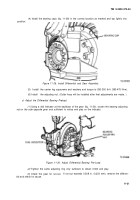

(4)

Position the drive pinion with spigot bearing pointing upward in a press and place the

staking tool over the pinion end and bearing, Apply a 3-3% ton pressure to the staking tool.

(5)

If new

CUPS

are to be installed, press the cups into cage using suitable sleeve. Make sure the

cups are firmly against the cage shoulders.

11-25

CAUTION

Back to Top