TM-9-2330-342-23-P - Page 327 of 1348

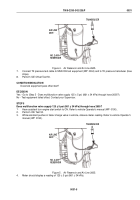

TRANSDUCER

AIR

CHAMBER

AIR LINE 2078

CHAMBER

ROD

FLATRACK

LOCKING

MECHANISM

AIR

CHAMBER

AIR LINE

2081

CHAMBER

ROD

Figure 6.

Flatrack Locking Mechanism.

2.

Visually inspect locking mechanism for bent, broken, and/or rusted components.

3.

Operate locking mechanism by hand.

4.

Ensure that locking components move freely and do not interfere with each other.

CONDITION/INDICATION

Are flatrack locking mechanism components free of damage?

DECISION

Mechanism OK - Go to (Step 7 - Does flatrack locking mechanism latch(es) unlock and remain unlocked?) to verify

problem is solved.

Mechanism Damaged - Replace damaged locking components (WP

0106). Go to (Step 7 - Does flatrack locking

mechanism latch(es) unlock and remain unlocked?) to verify problem is solved.

STEP 7

Does flatrack locking mechanism latch(es) unlock and remain unlocked?

1.

Pull out flatrack locking valve. Refer to TM 9-2330-342-10 (WP

0190).

2.

Pull out trailer charge valve in vehicle. Refer to vehicle Operator's manual (WP

0190).

3.

Turn OFF ENGINE switch. Refer to vehicle Operator's manual (WP

0190).

4.

Disconnect air hose 2078 or 2081 from TK pressure transducer (blue stripe).

5.

Connect air hose 2078 or 2081 to air chamber.

6.

Disconnect air hose 2080 from TK pressure transducer (blue stripe).

7.

Connect air hose 2080 to flatrack locking valve.

8.

Cage air chamber (WP

0105).

9.

Install upper locking pin in air chamber clevis (WP

0104).

10.

Uncage air chamber.

11.

Ensure vehicle is returned to normal operating condition.

12.

Push in flatrack locking valve. Refer to TM 9-2330-342-10 (WP

0190).

TM 9-2330-342-23&P

0030

0030-7

Back to Top