TM-9-2330-342-23-P - Page 325 of 1348

3.

Drain trailer air system. Refer to TM 9-2330-342-10 (WP

0190).

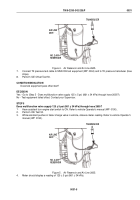

TRANSDUCER

AIR LINE

2078

AIR LINE

2080

FLATRACK

LOCKING

VALVE

Figure 4.

Flatrack Locking Valve and Air Lines 2078 and 2080.

4.

Disconnect air hose 2080 from TK pressure transducer (blue stripe).

5.

Connect air hose 2080 to flatrack locking valve.

6.

Disconnect air hose 2078 or 2081 from air chamber.

7.

Connect air hose 2078 or 2081 to TK pressure transducer (blue stripe).

8.

Push in flatrack locking valve. Refer to TM 9-2330-342-10 (WP

0190).

9.

Perform ICE Test 50.

10.

Have assistant push in trailer charge valve in vehicle. Refer to vehicle Operator's manual (WP

0190).

11.

Observe meter reading.

12.

Meter should display between 65 to 70 psi (443-483 kPa).

CONDITION/INDICATION

Does flatrack locking valve supply minimum 65 to 70 psi (443-483 kPa) to air chambers?

DECISION

Yes - Go to (Step 5 - Does air chamber(s) rod(s) move out?).

No - Replace flatrack locking valve (WP

0085). Go to (Step 7 - Does flatrack locking mechanism latch(es) unlock

and remain unlocked?) to verify problem is solved.

STEP 5

Does air chamber(s) rod(s) move out?

WARNING

Be sure to wear the proper eye protection when working on or around pressurized air systems

if not injury or death could result.

1.

Pull out flatrack locking valve. Refer to TM 9-2330-342-10 (WP

0190).

2.

Pull out trailer charge valve in vehicle. Refer to vehicle Operator's manual (WP

0190).

3.

Turn OFF ENGINE switch. Refer to vehicle Operator's manual (WP

0190).

4.

Disconnect air hose 2078 or 2081 from TK pressure transducer (blue stripe).

5.

Connect air hose 2078 or 2081 to air chamber.

6.

Cage air chamber (WP

0105).

7.

Remove upper locking pin from air chamber clevis (WP

0104).

8.

Uncage air chamber.

TM 9-2330-342-23&P

0030

0030-5

Back to Top