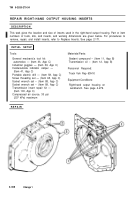

TM-9-2520-270-34 - Page 628 of 933

TM 9-2520-270-34

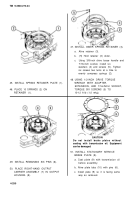

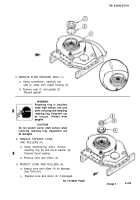

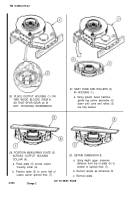

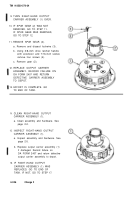

22. SEAT CARRIER ASSEMBLY (1) IN

HOUSING (2).

a. Using plastic faced hammer, gently

tap output housing collar (3) down

to seat carrier assembly (1).

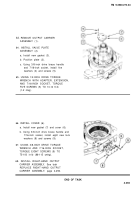

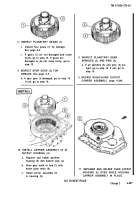

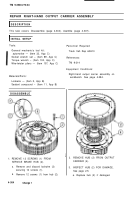

NOTE

The object of these calculations is to find

washer thickness needed to get correct end-

play of carrier assembly in housing.

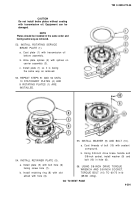

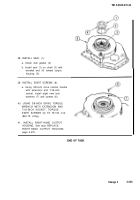

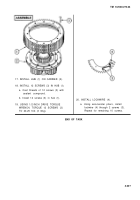

24. OBTAIN DIMENSION A.

a. Using depth gage, measure distance

from top of plate (4) to bottom of

splined hole (5).

b. Record results as dimension A.

c. Remove plate (4).

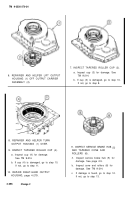

23. POSITION MEASURING PLATE (4)

ACROSS OUTPUT HOUSING

COLLAR (3).

a. Place plate (4) across output

collar (3).

b. Position plate (4) to cover

half of output carrier splined

hole (5).

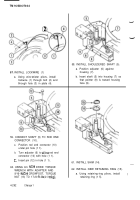

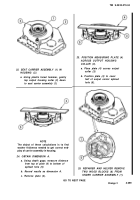

25. REPAIRER AND HELPER REMOVE

TWO WOOD BLOCKS (6) FROM

UNDER CARRIER ASSEMBLY (1).

GO TO NEXT PAGE

—

Change 2

4-299

Back to Top