TM-9-2815-205-34 - Page 462 of 596

TM 9-2815-205-34

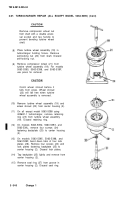

3-66. BLOWER REPAIR (Cont)

(14) Install twelve-point bolt (22) and right

blower drive pilot (23) in counterbore of

right gear (11). Install self-locking bolt

(24) and left blower drive pilot (25) in

counterbore of left ear (16). Torque bolts

to 25-30 Ib-ft (34-41 N-m).

(15) Remove rag from rotors. Check backlash

between gears (11 and 16) using dial

indicator. Backlash must be 0.0005 to

0.0025 inch with new gears and a

maximum of 0.0035 inch with used gears.

NOT E

Add or remove shims between

gear and rotor spacer until

blower clearances meet speci-

fications.

(16) Using stacked thickness gages, obtain

blower clearances as follows:

(a)

(b)

(c)

Measure clearance between rotor

lobes and blower housing at (B) and

(C). Take measurements across

entire length of each rotor lobe.

Clearance (C) must be 0.004 inch

minimum and clearance (B) must be

0.010 inch minimum.

Rotate gears until rotor lobes are at

their closest position. Measure

clearance (D) between rotor lobes

across entire length. Clearance must

be 0.009 inch minimum.

Measure clearance (E) between end

of rotors and blower end plates. Push

rotor toward end plate being

measured and hold at this position

while obtaining measurement. For

model 5063-5299, clearance must be

0.008 inch minimum at front end plate

and 0.010 inch minimum at rear end

plate. For all except model 5063-

5299, clearance must be 0.010 inch

minimum at front end plate and 0.012

inch minimum at rear end plate.

3-334

Back to Top