TM-9-2815-205-34 - Page 470 of 596

TM 9-2815-205-34

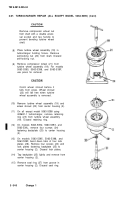

3-67. TURBOCHARGER REPAIR (ALL EXCEPT MODEL 5063-5299) (Cont)

b. Cleaning

Dry cleaning solvent P-D-680 is toxic and flammable. Wear protective goggles

and gloves and use In a well-ventilated area. Avoid contact with skin, e es, and

clothes. Do not breathe vapors. Do not use near open flame or excessive heat.

The flash point is 100-138°F 36-50°C). If you become dizzy while using cleaning

solvent, get fresh air immediately and seek medical aid.

If contact with eyes is

made, wash with water and get medical aid immediately.

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

CAUTION

Do not use a caustic solution to clean turbocharger. Do not use wire brush or steel

blade scraper to clean parts. Such cleaning will damage finished surfaces of

turbocharger.

NOT E

Before cleaning, inspect parts for signs of burning, rubbing, or other damage which

might not be evident after cleaning.

Ensure compressor and turbine wheel blades are thoroughly clean. Deposits left on

(1)

(2)

(3)

(4)

blades will affect balance of rotating assembly.

Soak all parts in cleaning solvent for 25 minutes. After soaking, use a stiff bristle brush to

remove all dirt particles. Using compressed air, dry all parts thoroughly.

Clean all internal cavities and oil passages in center housing thoroughly with compressed air.

Clean oil passage in center housing thrust plate with compressed air.

CAUTION

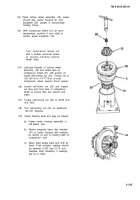

When polishing surfaces, use silicone carbide abrasive cloth for aluminum parts and

crocus cloth for steel parts.

Minor surface damage of nonbearing surfaces maybe burnished or polished away.

c. Inspection

(1)

(2)

3-342

Inspect all parts for signs of damage, corrosion, or deterioration. Check for nicked, crossed, or

stripped threads.

Check turbine wheel for nicks, rubbing, and wear.

Back to Top