TM-9-2815-213-34 - Page 90 of 192

C2,

TM 9-2815-213-34

Check oil pressure and water circulation: look leaks.

(1)

Apply dynamometer load to develop

horsepower at speed (rpm) indicated below.

Maximum Rated HP @ RPM-300@ 3000

Maximum Fuel Rate lbs./hr.-120

Maximum Crankcase Pressue-5

Valve and Injector Settings (130 degrees/150

degrees Fahrenheit)

Injector,

Inch-Pounds-50

Valves: Intake-14,

Exhaust-27

First ½h Hour HP@ RPM-75 @ 2000

Second % Hour HP @ RPM-125 @ 2500

Third % Hour HP @ RPM-150 @ 2700

Fourth ½ Hour HP @ RPM--250 @ 3000

Fifth ½'i Hour HP @ RPM-275 @ 3000

Power check 5 min.

maximum 96 percent Rated

Power-288 @ 3000

(2)

Check

crankcase

blow-by

(paragraph

below).

If not excessive,

reduce run-in time by one-half.

(3)

If blow-by is too high,

run engine for time

period shown under item (1) above.

(4)

At first period only: Run the engine until

temperature reaches 140 degrees Fahrenheit.

Add to

bring level up to "H" mark on dipstick.

(5)

At second period only: Reset valves and

injectors.

Set engine governed speed and fuel rate.

(6)

At third and thereafter: if blow-by is

excessive,

reduce load to preceding phase and run 30

minutes; then return to original sequence and continue

planned program.

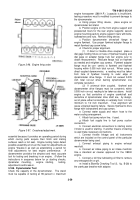

c. Blow-By Check.

(1)

Install right bank rocker housing.

Install

sealed type oil dipstick.

(2)

Install right bank rocker housing.

Install

sealed type oil dipstick.

(3)

Attach a manometer to the hose coupling

the checking too (fig 3-98),

and fill the tube w water to

the "0" mark at the middle of scale.

(4)

Manometer

readings

must

be

taken

frequently during the break-in test to note any blow-by

crease.

If there is any increase,

engine speed must

decreased for a few minutes and then brought back

original setting.

(5)

During each 5 minute power check,

keep a

constant check on the manometer.

If the press rises,

more run-in is required.

Maximum press limits for engine

running,

at governed speed a operating at 96 percent to

100 percent of rated horsepower are listed in paragraph

b (1),

above.

(6)

Observe variation in rate of blow-by during

initial engine run.

If the crankcase pressure,

or blow- by

is greater at the end of the testing period than maximum

values listed,

the engine should operated at 96-100

percent rated load and rpm for minutes.

If the blow-by is

not is' not increasing,

although it may be above 5 inches

of water (maximum crankcase pressure),

there is

generally no reason for concern.

As the rings and

cylinder liner combination wear in,

the blow should come

down below 5 inches of water.

If blow-by does not

decrease after 30 minutes,

continue to operate for up to

50 hours.

If blow-by is not below 5 inches of water within

50 hours of operation,

the engine must be considered

unacceptable.

d. Power Check.

(1)

Run engine ar rated speed for 5 minutes.

It

should indicate 96 percent of rated power at standard

fuel rate (120 pounds per hour).

Check crankcase blow-

by.

(2)

If crankcase blow-by exceeds value shown

(5 inches of water),

reduce engine speed and load to

preceding level.

Run engine 30 to 45 minutes.

(3)

Repeat procedures described above until

engine develops 96 percent power (288 horsepower) at

standard fuel rate (120 pounds per hour) within

permissible crankcase blow-by limit (5 inches of water).

CAUTION

Do not exceed 5 minute power check

limitation.

(4)

During power check,

check lubricating oil

as follows:

(a) Oil pressure at idle speed,

10 to 30

p.s.i.

@ 225 degrees Fahrenheit,

at maximum speed,

60 p.s.i.,

maximum.

Lubricating oil pressure should

remain at or near a constant figure at constant engine

speed and load,

after normal operating temperatures

have reached.

NOTE

Abnormally high oil pressures may

indicate restricted lubricating oil lines.

Low pressures indicate an insufficient oil

sup- ply or increased oil clearance which

may be due to bearing wear.

(b)

Under full load conditions,

oil pressure

may drop to 30 p.s.i.

and oil temperature may reach 250

degrees Fahrenheit to 265 degrees Fahrenheit to 265

degrees Fahrenheit for a short period.

This is not cause

for alarm.

CAUTION

Any sudden increase in oil temperature

which is not caused by loading increases

in a warning of possible mechanical

failure and should be investigated at

once.

(c)

After the first 5 to 10 minutes operation the

engine should be shut down and engine oil added to

compensate for engine oil absorbed by filters.

3-61

Back to Top