TM-9-2815-213-34 - Page 85 of 192

*TM 9-2815-213-34

c

. Remove locknut (2) securing pulley to shaft and

remove pulley and woodruff key (3).

d

. Remove two cap screws (14) lockwasher (12)

and flat spacer washers (15) securing pump (5) to

mounting bracket (4).

3-144.

Cleaning

Clean all components in accordance with procedures in

paragraph 2-5.

3-145.

Inspection

Perform

general

inspection

in

accordance

with

paragraph 2-6.

3-146.

Repair

Repair of the pump and brackets is limited to the

instructions contained in paragraph 2-7.

3-147.

Assembly

Refer to paragraph 3-143 and reverse procedures to

assembly the pump.

NOTE

Insure that flat spacer washers are

placed

between

pump

body

and

mounting bracket.

3-148.

Installation

a

.

Install pump and bracket assembly mounting

bracket on block and secure with three cap screws,

lockwashers and plain washers.

b

.

Install pump and bracket assembly on engine

mounting bracket and secure with two cap screws,

lockwashers,

and plain washers.

c

. Install pump drive belt on pulley.

d

. Install tension adjusting strap on engine block

with cap screw,

lockwasher and plain washer. Finger

tighten.

e

. Secure tension adjusting strap to pump

mounting bracket with cap screw,

lockwasher,

and plain

washer.

f

.

Adjust pump to obtain proper belt tension and

tighten tension strap to block securing cap-screw.

Section XXVII.

Repair of Alternator Assembly and Mounting Bracket.

3-149.

Disassembly

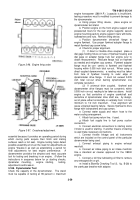

(fig.

B-24)

a

.

Remove locknut from shaft and remove two

sheave pulley and key.

b

.

Remove cap screw and lockwasher securing

adjusting arm to alternator end plate.

3-150.

Cleaning

Clean all components in accordance with procedures in

paragraph 2-5.

3-151.

Inspection

Perform general inspection in accordance with the

requirements of paragraph 2-6.

3-152.

Repair

Repair of the alternator and bracket is limited to the

instructions of paragraph 2-7.

The alternator shall be

replaced if noisy or voltage cannot be maintained

between 27-29 volts.

3-153.

Assembly

Refer to paragraph 3-149 and reverse disassembly

procedures.

3-154.

Installation

Refer to paragraph 2-lO.c.,

and reverse removal

procedures.

Section XXVIII.

Repair of Starter Assembly

3-155.

Inspection and Repair

Refer to TM 9-2920-242-34 for inspection and repair

procedures,

and repair parts listing.

3-156.

Installation

Refer to paragraph 2-10.a.,

and reverse removal

procedures.

Section XXIX.

Repair of Oil Cooler

3-157.

Disassembly

(fig.

B-1l)

a.

Remove transmitter (16) and bushing (17) from

pipe tee (18).

b

. Remove pipe plug (5) and (10).

c

.

Remove five cap screws (23) and lockwasher (7)

securing cover (12) to housing (22).

d

.

Remove gasket (13) O-Rings (24) retainer

(14) and filter element (15).

3-158.

Cleaning

a. Oil Side.

CAUTION

Perform the following operation in a well

ventilated area to avoid toxic effect of

chemicals being used.

3-56

Back to Top