TM-9-2815-213-34 - Page 91 of 192

C2,

TM 9-2815-213-34

Thereafter,

check oil level of the engine,

with the

dipstick every two (2) hours during run-in test.

Maintain

oil level at "H" mark on the dipstick.

(5)

Check engine coolant as follows:

(a)

After engine is started,

add coolant as

required to completely fill cooling system and replace

entrapped air.

(b)

The ideal water temperature is 175

degrees Fahrenheit for best engine performance.

It

should ] exceed 190 degrees Fahrenheit during

operation.

(c)

Do not turn off engine immediately after

load operation.

Heat stored in the iron masses will boil

cooling water in the jackets if air and water circulation

cease while engine is still hot.

Allow engine to idle for a

few minutes before shutting down.

(6)

Check fuel pressures as follows.

(a)

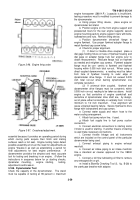

Check fuel manifold pressure with f

system pressure gage (4,

fig.

B-29) as shown figure 3-

99.

Accelerate from idle to full throttle a record

maximum pressure recorded on gage; it should be 202

to 218 pounds.

(b)

Check fuel rate with fuel flow rate check

gage (2,

fig.

B-24) as shown in figure 3-100.1 gage’s

flow tank is placed between the engine and t fuel supply

tank.

Fuel return line(s) and the f pump suction line are

then attached to the circulating tank.

NOTE

As the engine burns fuel,

the float valve

allows make-up fuel to flow into the cir-

culating tank from the fuel supply tank.

This make-up fuel passes through the

flowmeter and is the fuel rate of the

engine registered in pounds per hour.

Fuel rate is 120 pounds per hour.

(c)

Accelerate engine from idle to full

throttle and check manifold pressure with Pressure

Gage.

It should be 202 to 218 pounds.

(d)

Refer to Section XIX Fuel Pump for fuel

pump governor adjustments.

(e)

Inspect all fuel lines and connections for

leaks and security of mounting.

(f)

Inspect lubricating oil connections for

leaks.

Check oil cooler for security of mounting and in-

let/outlet connections for leaks.

(g)

After run-in has been completed,

load

applications should be minimal for the first 50 hours of

operation.

This gives new parts a chance to "wear- in"

without undue stress and strain.

3-173.

Performance Curve

Figure 3-101 is an engine performance curve.

Solid

lines represent maximum ratings at 500 feet altitude

29.38 inches mercury and 85 degrees Fahrenheit

ambient air temperature.

The dotted lines indicate

standard sea level conditions.

These curves indicate

engine performance with fuel system,

water pump,

lubricating oil pump and air cleaner.

It does not include

battery charging generator,

compressor,

fan and

optional equipment.

Section XXXIII.

REPAIR AND REBUILD STANDARDS

3-174.

General

The repair and rebuild standards give maximum

minimum,

and key clearances of new or rebuilt pa Wear

limits are given,

which indicate the point which a part or

parts may be worn,

in order to receive maximum service

before replacement.

Normally,

parts which have not

been worn beyond the dimensions shown in "Wear

Limits" column will be

proved for further service.

An asterisk in the "Wear

Limits" column indicates that the part or parts should be

replaced when worn beyond the limits given in the "New

Dimensions" column.

All dimensions are given in inches.

3-175.

Cylinder Block

(para 3-4)

3-62

Back to Top