TM-9-2815-213-34 - Page 86 of 192

*TM 9-2815-213-34

(1)

Immerse the filter element in carbon

tetrachloride to trichloethylene,

or other approved

cleaning solvent.

(2)

Using a rubber suction cup force solvent

around and through the tubes until clean.

NOTE

If all passages are badly clogged,

circulate an oakite or alkaline solution

through the tubes.

(3)

After cleaning flush thoroughly with hot

water.

b. Water Side.

(1)

Plug oil inlet and outlet.

(2)

Immerse oil cooler in solution of one part

muriatic acid,

nine parts water,

one pound oxalic acid,

and 0.01 gallon of pyridene to each five gallons of acid.

(3)

Remove core when foaming and bubbling

stops.

This usually takes 30 to 60 seconds.

(4)

Immerse unit in a 5 percent solution sodium

carbonate.

Remove when bubbling stops and pressure

flush with clean warm water.

(5)

Clean’ inside of case thoroughly will steam

or solvent.

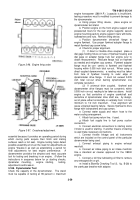

3-159.

Inspection

a.

Perform general inspection in accordant with

paragraph 2-6.

b.

Assembly oil cooler.

Plug oil outlet and attach

70/100 p.s.i.

air line to oil inlet.

c.

Immerse unit in water and apply air pressure.

The slightest leak will be indicated by the appearance of

air bubbles.

d.

Assemble front and rear heads to cooler.

e.

Plug either inlet or outlet connection and check

for leaks as described in steps (1) and (2) above.

3-160.

Repair

a.

Header leaks may occur where tubes protrude

through header plate or where header is soldered.

The

header may become cracked in service due to excessive

pressure.

Resolder tubes to header as necessary.

CAUTION

Do not burn tubes or header material with torch flame.

b.

Perform general repairs in accordance with

paragraph 2-7.

3-161.

Assembly

Assemble cooler in reverse order of disassembly (para

3-157),

and perform a leak test.

CAUTION

Insure element is assembled so "O"

marks are aligned on case and element.

Section XXX.

REPAIR OF EXHAUST MANIFOLDS

3-162.

Cleaning

Clean manifolds in accordance with instructions in

paragraph 2-5.

3-163.

Inspection

Inspect manifolds in accordance with instructions in

paragraph 2-6.

3-164.

Installation

(right bank)

Secure manifold to head with eight cap screws,

spacers,

four lockplates,

and four gaskets.

Section XXXI.

ENGINE REMOVAL FROM REBUILD STAND

3-165.

General

Attach lifting hooks to hoist to front and rear engine lifting

eyes (fig.

1-1 and 1-2),

and takes slack in chain.

3-166.

Rebuild Stand Removal

a.

Remove cap screws and lockwasher securing

engine stand and adapter plate to engine block.

b

. Remove stand and adapter from engine.

c.

Install gasket and left side cover plate to block securing

with 12 cap screws and lockwashers.

d

. Install oil cooler and four gaskets securing with

13 cap screws and lockwashers to block and cover plate.

e

. Install left bank manifold and four gaskets to

cylinder head securing with eight cap screws,

spacers,

and four lockplates.

Section XXXII.

ENGINE TEST AND ADJUSTMENT

3-167.

Adjustment

a

. Injectors,

Crossheads,

and Valves.

(1)

Injector plungers,

crossheads and valve

must be adjusted before starting engine first time at cold

setting and-again during engine test after

reaching operating temperature.

(2) Always adjust injectors before crossheads and

valves.

3-57

Back to Top