TM-9-2815-213-34 - Page 84 of 192

*TM 9-2815-213-34

Section XXV.

Repair of Fan,

Fan Hub,

and Bracket Assembly

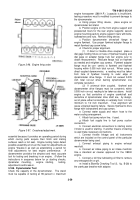

3-137.

Disassembly

(fig.

B23).

a

. Remove six cap screws (1) and lockwashers (2)

securing fan (3) fan spacer (4) pilot spacer (6) to seven

sheave pulley (11).

b

. Pull cotter pin and remove nut (7) washer (8)

from shaft (13).

c

. Press shaft from pulley.

d

. Remove bearings (9) and oil seal (12).

e

. Using suitable puller remove bearing outer races

(10).

3-138.

Cleaning

Clean all components in accordance with procedures in

paragraph 2-5.

3-139.

Inspection

a

. Inspect bearing cone and rollers,

and tape roller

bearing cup (rear).

Replace if damaged,

rough or worn.

b

. Inspect threads for stripped or crossed threads.

Replace all damaged parts.

c.

Inspect fan hub nut,

idler seal,

and idler fan hub

shaft for damage or wear.

Replace if damaged or worn.

d

perform general inspection in accords with

paragraph 2-6.

3-140.

Repair

Repair of the assembly is limited to the instructions in

paragraph 2-7.

3-141.

Assembly

CAUTION

Aline shaft in bearing before pressing.

Use only enough pressure to slide

bearing over the shaft.

a

. Using suitable arbor press install o races of

tapered bearings into fan hub hour with cupped area up.

Outer races must against shoulders provided in housing.

b.

Pack bearing cones of both bearings ’with GAA.

c.

Install pipe plugs in housing.

Seal plugs with

sealing tape or sealer to prevent leaks.

d

. Install rear bearing inner race with largest inside

diameter into rear of fan hub and press new oil seal into

housing flush with bore.

e

. Install shaft through oil seal and bearing inner

race.

Seat with light tapping of a soft hammer or press.

f.

Fill cavity between bearings ½

to %

full of GAA.

g

. Install front bearing,

clamp washer,

and

retaining nut.

h.

Slowly rotate housing around spindle and at the

same time tighten retaining nut until a small "drag" is felt

during rotation of housing.

CAUTION

Hub must be rotated while nut is being

tightened.

Failure to rotate hub will

result in excessive end play.

i.

Tap fan hub assembly lightly with a soft hammer

to relieve clearances.

Check shaft end clearance.

It

must be 0.001/0.007 inch and the hub must rotate freely.

Loosen or tighten nut and repeat step h above,

if

required.

Lock retaining nut with cotter pin.

j

. Apply GAA to outer bearing.

Assemble new

gasket,

spacer,

and fan to pulley assembly with

lockwashers and cap screws.

3-142.

Installation

a

. Install fan assembly bracket on block (fig.

24)

and secure with six cap screws and lock- washers.

b

. Position flatwasher on shaft and insert shaft in

bracket.

Secure with flatwasher and lock nut.

c

. Install adjusting bolt in bracket and through

shaft.

d

. Set hydraulic pump drive belt on inner sheave,

and two alternator drive belts on next two sheaves.

e.

Install three drive belts from crankshaft drive

pulley to three outer sheaves of fan drive pulley.

Section XXVI.

Repair of Hydraulic Pump and Mounting Bracket

NOTE

If engine is received for repair without

the power steering pump (hydraulic

pump),

bracket,

pulley and drive belt,

do not requisition these items for instal-

lation on the repaired engine.

The re-

paired or rebuilt engine will be shipped

to the using unit without the pump assembly.

3-143.

Disassembly

(fig.

B-26).

a

. Remove swivel elbow (7) and nipple (6).

b

. Remove adapter (10) bushing (9) and elbow (8).

3-55

Back to Top