TM-9-2815-213-34 - Page 79 of 192

*TM 9-2815-213-34

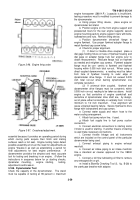

Figure 3-92.

Governor spring shimming.

p.p.h.

with throttle fully open (3000 RPM).

(b)

Reduce speed to 500 rpm.

(c

Set 4-way valve to "LEAKA TEST"

position.

(d)

Turn count selector switch to 1000 pulse

position (fig.

3-80).

NOTE

Fuel delivery should be 35cc-plus or

minus 5-cc for a one minute period.

The

test stand has a maximum count of 1000

strokes,

therefore,

at 3000 RPM each

cycle will be of one-third minute duration,

and the fuel delivery will also be one-

third the above cc valves.

(e)

Pull out

fuel dumping lever ( 3-80).

(f)

Remove throttle spring and manually

operate throttle.

(g)

Depress pulse counter button to No.

1

burette (fig.

3-80) and push in fuel dumping lever.

NOTE

Burette will overflow before cycle is

completed,

therefore,

it is important to

push-in fuel dumping lever and return

throttle to idle position when burette is

filled.

(h)

Increase speed to 3000 rpm and h

(i)

Pull out fuel dumping lever and press

counter button to start count.

NOTE

At completion of count cycle the fuel de-

livery in No.

1 burette should be 10 to

13.5 cc.

If not to specification adjust

throttle stop screw (fig.

3-93) until fuel

delivery is to specification and lock

setting.

(6)

Set Idle Speed

.

(a)

Set throttle shaft to idle position.

(b)

Set 4-way valve to "IDLE" position.

(c)

Set speed to 600 rpm.

NOTE

Reading on pressure gage should be 22

p.s.i. If pressure is low,

adjust idle

adjusting screw using idle adjusting tool

(32,

fig.

B-28) as shown in figure 3-94.

(Remove pipe plug to insert tool).

To

lower pressure,

back-out screw.

If

pressure is low,

and screw bottoms on

guide, washers will have to be added to

the spring end of the screw.

(

d

Each time pipe plug is removed to

adjust idle screw,

run pump until purged of air.

(7)

Check Point Flow Tests.

(a

) Set 4-way valve to "ROTAMETER"

position.

(b)

Set throttle to full open position.

(c)

Operate pump at 2500 rpm and adjust

flow to 445 p.p.h.

Pressure gage should read 165-173

p.s.i.

(d)

Reduce speed to 2000 rpm and adjust

flow to 335 p.p.h.

Pressure gage should read 117-125

p.s.i.

(e)

Reduce speed to 800 rpm and adjust

Figure 3-93.

Throttle stop screw adjust.

3-50

Back to Top