TM-9-2815-213-34 - Page 83 of 192

*TM 9-2815-213-34

NOTE

Driving flange of seal case must seat

properly on edge of bore in pump body.

j

.

Support pump on pulley end of shaft.

Pr on impeller and maintain 0.010/0.020

inch

clearance between impeller vanes and pump body.

3-1 24.

Installation

Position water pump and new gasket to cylinder block

and secure with five cap screws and lock.

washers.

Section XXIII.

Repair of Fan Drive Pulley,

Vibration Damper,

and Water Pump Pulley Assembly

3-125.

Disassembly

Using a soft hammer or brass driver, remove vibration

damper from water pump drive pulley hub.

3-126.

Cleaning

Refer to paragraph 2-5 for cleaning procedure

3-127.

Inspection

Refer to paragraph 26 for inspection procedure

3-128.

Repair

Repair of the assembly is limited to the procedures of

paragraph 27.

3-129.

Assembly

Press vibration damper onto water pump pulley hub.

Insure that cap screw holes are aligned.

3-130.

Installation

a

. Loosen adjustable sheave on water pump and

set crankshaft-to-pump drive belt in pulley.

b

. Set water pump drive belt on drive pulley.

c.

Position pulley and damper assembly on crankshaft

flange.

d

.

Position three sheave fan drive pulley to vibration

damper and secure to crankshaft with seven cap screws

and lockwashers.

e

. Tighten water pump pulley adjustable sheave to

obtain required belt tension.

Section XXIV.

Repair of Thermostat Assembly

3-131.

Disassembly

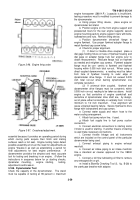

(fig.

B-21).

a

.

Remove two cap screws (16) lockwasher and

flat washer (15) securing thermostat cover (14) to

housing (7).

b

.

Remove thermostat (12) and gasket (13)

c

.

Remove pipe plugs (10) and temperature transmitter

(11).

d

.

Loosen hose clamp and remove hose.

3-132.

Cleaning

Refer to paragraph 2-5 for cleaning procedure:

3-133.

Inspection

a

.

Perform general inspection in accordance with

paragraph 26.

b

.

Check thermostat as follows:

(1) Immerse thermostat and thermometer in

water.

NOTE

Season

thermostat

by

operating

thermostat for a period of 45 minutes at

200 degrees Fahrenheit.

(2)

Cool

water

to

the

initial

operating

temperature, 173 degrees

Fahrenheit

of the

thermostat.

(3)

Compare

thermostat

operation

with

temperature indicated on thermometer.

c

.

The high range thermostats installed on the V8-

300 engine start to open at 173 degrees Fahrenheit and

are fully open at 186 degrees Fahrenheit.

d

.

Discard thermostats not operating in correct

range.

Replace with same range thermostat.

e

. Inspect thermostat for physical damage.

If

damaged,

replace thermostat.

3-134.

Repair

Refer to paragraph 2-7 for general repair procedures.

3-135.

Assembly

Refer to paragraph 3-131 and reverse procedures.

3-136.

Installation

a

. Position thermostat housing with new gasket to

cylinder head and secure with four cap- screws and

lockwashers.

b

. Position hose on water pump and tighten hose

clamps.

3-54

Back to Top