TM-9-2815-213-34 - Page 89 of 192

*TM 9-2815-213-34

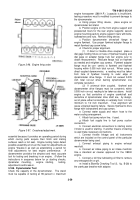

Also,

connect a manometer to the Blow-By

Tool

measure the amount of blow-by gases escaping past the

piston rings.

NOTE

This is essential to indicate seating of

rings and to ascertain if and when

additional run-in time is necessary.

3-170.

Preparation For Starting

As an assist in priming the fuel and lubricating oil s3-

stems it is recommended that all filter: removed and

serviced with their respective

a.

Prime fuel pump before starting engine the first

time.

Remove plug next to tachometer drive and fill with

clean diesel fuel.

b

. Check Fuel Tanks.

There must be an adequate

supply of good grade,

clean diesel fuel the tanks.

c.

Close all drain cocks and open vent cocks,

on

air compressor and vent (pipe plugs) water crossover

tubes to insure circulation.

d.

Fill engine with required coolants until it flows

from vent cocks and vents; close all vents and fill the

system.

e

. Fill oil pan to "L" (low) mark on dipstick.

f.

Connect a hand or motor driven priming pump

line from a source of clean OES-20 It lubricating oil to Oil

Cooler (Left Bank) "INL OUTLET" connections,

fill oil

pan to "H" position of the dipstick.

g

. Prime until a 30 psi minimum pressure obtained.

h

. Crank engine for at least 15 seconds while

maintaining external oil pressure at a minimum of 15 psi.

i

. Allow engine to fire and operate 5 to seconds.

j.

Remove external oil supply and replace full flow

oil filter system as used on the vehicle.

k

. Fill crankcase with oil to "H" (high) n on dipstick.

Grades used,

OES-10,

OES-2( OES-30,

will depend on

ambient temperature.

special oil is required for break-in

period.

change in oil viscosity or type is needed for or

newly rebuilt engines.

CAUTION

Service engine oil after a few minutes of

operation

to

compensate

for

oil

absorbed into filter- elements and

leakage.

l.

Check Oil Level.

Add oil if necessary to reach

the "H" level on the dipstick.

Never operate engine

below "L" mark or above "H” mark.

3-171.

Starting Engine

a

. Position the throttle at idle speed.

b

. Disengage the drive unit.

c

. Electrical shut-down valve operates (opens)

automatically.

NOTE

A manual override knob provided on the

forward end of the electric shut-down

valve allows the valve to be opened in

case of electric power failure.

To

operate "open" by turning fully clockwise.

d

. Press starter button or turn switch-key to "start"

position.

e

. Warm-up engine.

f.

Check all tubing,

hoses,

lines,

fittings and

plugs for leaks.

Correct as necessary.

g. Open cooling water supply valves to heat

exchanger.

Introduce water to absorption unit per

manufacturers instructions.

3-172.

Test Procedure

NOTE

Dynamometer manufacturers provide a

figure known as a "brake constant" with

each dynamometer.

This simplifies

computing brake horsepower,

since

only engine rpm and the scale reading in

pounds need be found.

a

. Horsepower Ratings.

(1)

The maximum horsepower rating 300 at

3000 rpm is established for engines on number 1 curve

in figure 101 in automotive or intermit- tent-duty

applications at sea level,

60 degrees Fahrenheit intake

air temperature and 29.92 inches Hg.

(Mercury

barometric pressure).

(2)

Where necessary an engine may be de-

rated because of high altitude-operation or for the sake

of fuel economy,

the derating may be done by reducing

governed rpm or maximum fuel rate in the proportion

desired.

(3)

Naturally-aspirated

engines

must

be

derated 3 percent for each 1000 feet altitude above sea

level,

and 1 percent for each 10 degrees Fahrenheit

ambient temperature rise above 60 degrees Fahrenheit.

(4)

New or rebuilt engines during dyna-

mometer test are not required to deliver more than 96

percent of maximum horsepower at power checks.

The

additional 4 percent will be achieved after a few hours

operation.

b.

Break-In-Run.

Start engine and idle at

approximately 800 rpm no-load for 5 to 10 minutes.

3-60

Back to Top