TM-9-1200-215-34-P - Page 143 of 266

TM 9–1200–215–34&P

5–5

J1

A

B

C

D

E

F

G

H

L

M

N

P

T

U

V

W

X

Y

Z

a

b

c

39

38

37

36

4

3

6

5

35

34

20

40

1

2

8

7

10

9

31

30

33

32

P3

J

K

R

S

30

1

20

21

21

22

25

26

27

28

13

14

15

16

17

19

22

23

16

25

27

29

26

28

WIRE

J2

P3

P4

P3

24

18

A

B

E2

E1

2

3

24

29

C

D

P4

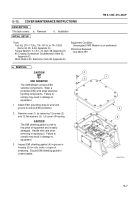

Figure 5–2.

VMS Cable Assembly

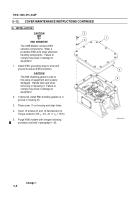

2.

If instances of noncontinuity are found between contacts, recheck applicable wires and contacts for fraying,

breakage, or corrosion.

3.

If contacts were found to be broken or corroded, forward unit to depot for repair of receptacle contacts,

connector contacts, or power distribution module contacts as appropriate.

4.

If noncontinuity exists between two points and the contact is not visibly damaged, forward unit to depot for

repair of applicable wire.

5.

If at this point, no failures have been identified in this cable, perform next higher assembly fault isolation

under the assumption that this cable assembly is functioning properly.

5–11.

POST–MAINTENANCE TEST

Follow the procedures outlined in TPS 12958912 to verify the operation of the VMS Modem.

Back to Top