TM-9-2350-260-20-1-3 - Page 522 of 783

TM 9-2350-260-20-1-3

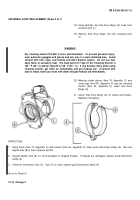

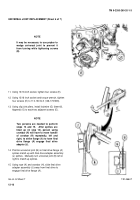

UNIVERSAL JOINT REPLACEMENT (Sheet 4.1 of 7)

NOTE

4.

Check staking of pin (C).

Stake marks should be on

flange (D) and overlapping pin (C) on four sides.

5.

If not staked properly, use fabricated center punch

and stake pin (C) four places, equally spaced on

flange (D).

If chamfer on flange (D) is so large that

metal does not mushroom over pin (C) when staked,

replace quick-disconnect clamp (A).

6.

Inspect quick-disconnect clamp (A) for cracks,

breaks, or sprung hinge.

If damaged, replace quick-

disconnect clamp (A).

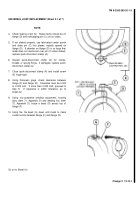

7.

Close quick-disconnect clamp (A) and install screw

(E) finger tight.

8.

Using thickness gage, check clearance between

flange (F) and flange (D).

Clearance must be 0.000

to 0.005 inch.

If more than 0.005 inch, proceed to

step 9.

If clearance is within tolerance, go to

sheet 4.2.

9.

Using oxy-acetylene welding equipment, brazing

alloy (Item 71, Appendix D) and welding flux (Item

72, Appendix D), braze a bead (G) across top of

flange (F).

10. Using file, file bead (G) down until metal to metal

contact exists between flange (F) and flange (D).

Go on to Sheet 4.2

Change 2

12-14.1

Back to Top