TM-9-2350-260-20-1-3 - Page 518 of 783

TM 9-2350-260-20-1-3

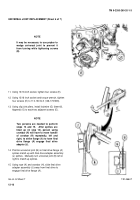

UNIVERSAL JOINT REPLACEMENT (Sheet 1 of 7)

PROCEDURE INDEX

PROCEDURE

PAGE

Removal

12-12

Inspection

12-14

Installation

12-14.2

TOOLS:

13/16 in.

socket with 1/2 in.

drive

Thickness gage

2 in.

extension with 1/2 in.

drive

Oxy-acetylene welding equipment

Ratchet with 1/2 in.

drive

10 in.

flat file

Hinged socket wrench handle with 1/2 in.

drive

92 lb.

minimum capacity hoist

Torque wrench with 1/2 in.

drive

3/4 in.

socket with 1/2 in.

drive

(0-175 lb-ft) (0-237 N

•

m)

1-1/2 in.

open end wrench

Diagonal cutting pliers

Slip joint pliers

Aligning punch

Pinch bar

Crowbar

Hammer

Screwdriver

SPECIAL TOOLS:

Center punch (Figure F-9, Appendix F)

SUPPLIES:

Lockwire (Item 60, Appendix D)

Paint brush (Item 70, Appendix D)

Dry cleaning solvent (Item 54, Appendix D)

Brazing alloy (Item 71, Appendix D)

Rags (Item 65, Appendix D)

Welding flux (Item 72, Appendix D)

Rope (Item 64, Appendix D)

Industrial goggles (Item 73, Appendix D)

Rubber gloves (Item 74, Appendix D)

PERSONNEL: Two

REFERENCES:TM 9-2350-260-10

LO 9-2350-260-12

PRELIMINARY PROCEDURES:Remove top deck (page 16-20)

Remove transmission shroud (page 9-20)

Remove transmission shroud support (page 9-38)

Remove exhaust pipe (left, page 8-6) or (right, page 8-10)

Block both tracks front and rear, place transmission selector lever

in neutral (N), and make sure brake is released so transmission

output flange can be turned to loosen all four screws

(TM 9-2350-260-10)

Pull transmission mounting guide toward rear (page 5-10)

Go on to Sheet 2

Change 2

12-11

Back to Top