TM-9-2815-210-34-2-2 - Page 143 of 968

TM 9-2815-210-34-2-2

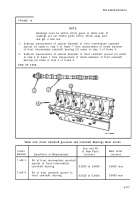

FRAME 4

1.

2.

3.

4.

NOTE

No special tools are needed to put in cylinder sleeves (l).

If old cylinder sleeves are used again, they must be put

back in the same cylinder bore (2) they were taken from.

Coat six cylinder sleeves (1) with engine lubricating oil and put one into each

of six cylinder bores (1).

Y-size cylinder sleeves must go in Y-size cylinder

bores.

Z-size cylinder sleeves must go in Z-size cylinder bores.

Using block gage, measure and note height of top of each cylinder sleeve

(1) from top surface of crankcase (3).

Cylinder sleeve is properly seated

when this height is 0.0005 to 0.005 inch.

If height is more than 0.005

inch, push cylinder sleeve further in.

Subtract biggest and smallest measurement done on three cylinder sleeves (1)

closest to front of crankcase (3).

Difference should not be more than 0.002

inch. If difference is bigger, push highest cylinder sleeves further down

and check heights again.

Do step 3 again for the three cylinder sleeves (1) closest to rear of crankcase

(3).

GO TO FRAME 5

4-124

Back to Top