TM-9-2815-210-34-2-2 - Page 144 of 968

TM 9-2815-210-34-2-2

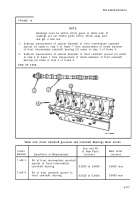

FRAME 5

1.

2.

NOTE

Readings must be within limits givien in table 4-29.

The letter L shows a loose fit.

If readings are not

within given limits, throw away part and get a new

one.

Cylinder sleeves (1) can be a little bit out-of-round

before they are put in cylinder bores in crankcase (2).

Because of this, it is not practical to measure cylinder

sleeve diameter when cylinder sleeves are out of

cylinder bores. Outside diameter of cylinder sleeves

and fit of cylinder sleeves in cylinder bores is given

in table 4-29 for reference purposes only.

Measure inside diameter of six cylinder sleeves (1) inside crankcase (2). Take

measurement one inch from top of cylinder sleeve.

Turn crankcase (2) upside down.

END OF TASK

Index

Number

1

l and 2

1

Table 4-29. Cylinder Sleeve Wear Limits

Size and Fit

of New Parts

Item/Point of Measurement

(inches)

Cylinder sleeve outside diameter

4.7500 to 4.7510

Fit of cylinder sleeve in bore of

crankcase

0.0005L to 0.0015L

Cylinder sleeve inside diameter

(cylinder sleeve in crankcase)

4.5630 to 4.5645

Wear Limit

(inches)

None

None

4.5665

4-125

Back to Top