TM-9-2815-205-34 - Page 480 of 596

TM 9-2815-205-34

3-68. GOVERNOR REPAIR (Cont)

b. Cleaning/Inspection

(1)

(2)

(3)

(4)

(5)

Drycleaning solvent P-D-680 is toxic and flammable. Wear protective goggles

and gloves and use in a well-ventilated area. Avoid contact with skin, eyes, and

clothes. Do not breathe vapors. Do not use near open flame or excessive heat.

The flash point is 100-138°F (38-50°C). If you become dizzy while using cleaning

solvent, get fresh air immediately and seek medical aid. If contact with eyes is

made, wash with water and get medical aid immediately.

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

Clean ail parts with cleaning solvent and dry with compressed air.

Inspect bearings for corrosion or pitting. Revolve bearings by hand and check for rough or tight

spots.

Inspect needle bearings in control link lever assembly and mating lever pin for wear.

Inspect governor springs, spring seat, spring cap, plunger, spring retainer, adjusting screws,

and other parts of governor for wear.

Inspect governor housing for cracks,

warpage, and damaged threads.

c. Assembly

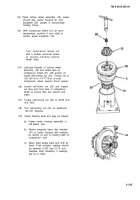

(1) Governor cover

(a)

(b)

(c)

(d)

(e)

3-352

If removed, press two pins (19) in

bottom of cover (9) until flush to 0.005

inch below machined surface.

If bushings (20) were removed, place

governor cover (9), inner face down,

in press. Start bushing straight into

bore, numbered side up. Place

bearing installer (72) in bushing and

press until shoulder of installer

contacts cover. Invert cover and

install second bushing (20) in same

manner.

Lubricate throttle shaft (4) with engine

oil and slide into bushings from

bottom of cover with lever pin (73) in

slot on underside of cover.

Install preformed packing (10), shouldered washer (8), fiat washer (7), and retaining ring (6)

over throttle shaft (4).

Install pin (17) into stop lever shaft (16). Press pin into shaft, from side with fiat spots, until

flared end of pin protrudes 1/4 inch.

Back to Top